- Home

- Products

- Architectural & Decorative Mesh

- Hex Steel

Hex Steel

Application:

1. Hex steel as refractory material has flexibility, high strength and anti-erosion properties. Hex steel is nice choice of furnace, reactor, cyclone separator, pipes, fire-resistant liner of flue. The degree of high temperature resistance is 700 ℃ -1600 ℃. The hex steel is developed newly, and the load capacity can reach 7400N/m2. High temperature resistant unshaped lining material is usually reinforced by hex steel. Carbon steel (A3F) hex steel uses 0Cr13 materials in special case. The hex steel is spot-weld on the inner wall of boiler or hot air duct and then smeared by refractory material.

2. Hex steel is used for floor. Hex steel provide long-term protection for armoring of industrial floor. Loading wharf, ramps, traffic passages of forklifts and trucks, hot floors of foundries, forgings and steel mills, floor of waste treatment plant and almost any floor will be severely impacted, so using hex steel can increase stress area, strengthen bearing capacity of floor and improve the service life of bottom plate.

Material: common carbon steel, 0Cr13, 1Cr13, 0Cr18Ni9 and 1Cr18Ni9Ti.

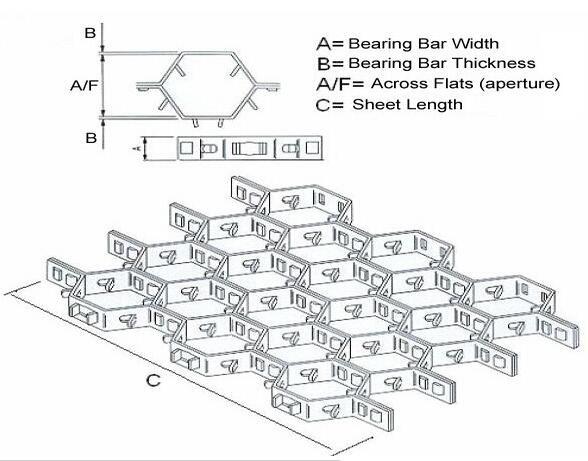

Specifications:| HEX-MESH / HEXMETAL / HEXSTEEL | |||||

| ITEM | SPECS | B | A | AF | |

| 1 | 1.2 X 10 X 50mm | 1.2mm | 10mm | 40mm | |

| 2 | 1.2 X 15 X 50mm | 1.2mm | 15mm | 50mm | |

| 3 | 1.2 X 20 X 50mm | 1.2mm | 20mm | 50mm | |

| 4 | 1.5 X 10 X 50mm | 1.5mm | 10mm | 50mm | |

| 5 | 1.5 X 15 X 50mm | 1.5mm | 15mm | 50mm | |

| 6 | 1.5 X 20 X 50mm | 1.5mm | 20mm | 50mm | |

| 7 | 1.8 X 15 X 50mm | 1.8mm | 15mm | 50mm | |

| 8 | 1.8 X 20 X 50mm | 1.8mm | 20mm | 50mm | |

| 9 | 1.8 X 25 X 50mm | 1.8mm | 25mm | 50mm | |

| 10 | 2.0 X 15 X 50mm | 2.0mm | 15mm | 50mm | |

| 11 | 2.0 X 20 X 50mm | 2.0mm | 20mm | 50mm | |

| 12 | 2.0 X 25 X 50mm | 2.0mm | 25mm | 50mm | |

| 13 | 2.0 X 30 X 50mm | 2.0mm | 30mm | 50mm | |

| 14 | 2.0 X 30 X 80mm | 2.0mm | 30mm | 80mm | |

| Remark | A/F | Min: 40mm Max: 100mm | |||

| MATERIAL | A3 ,0Cr13,1Cr13,SS304,SS316,1Cr18Ni9Ti, 310S, 410S | ||||

| Anchorage Material | Chemical Composition | Typical Service Temperature | ||||||||

| AISI | DIN | C% | Si% | Mn% | P% | S% | Cr% | Ni% | others | |

| 304 | 1.4301 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.45 | ≤0.30 | 18.0-20.0 | 8.0-10.0 | N | 800℃ |

| 316 | 1.4401/1.4436 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.45 | ≤0.30 | 16.0-18.0 | 10.0-14.0 | N:Mo | 800℃ |

| 321 | 1.4541 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.45 | ≤0.30 | 17.0-19.0 | 9.0-12.0 | Ti | 800℃ |

| 310S | 1.4845 | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.45 | ≤0.30 | 24.0-26.0 | 19.0-22.0 | - | 1150℃ |

| Inconel 601 | 2.4851 | ≤0.10 | ≤0.50 | ≤1.00 | - | ≤0.15 | 21.0-25.0 | 58.0-63.0 | Al:Cu | 1200℃ |

| Inconel 800 | 1.4876 | ≤0.10 | ≤1.00 | ≤1.50 | ≤0.45 | ≤0.15 | 19.0-23.0 | 30.0-35.0 | Al:Ti | 1200℃ |

| 410S | 1.4001 | ≤0.08 | ≤1.00 | ≤1.00 | ≤0.40 | ≤0.30 | 11.5-13.5 | ≤0.60 | - | 750℃ |

| CARBON STEEL | VARIOUS | 550℃ | ||||||||

Hex steel is made of special high temperature resistant and corrosion resistant metal materials punched by professional device and assembled to hexagonal stereoscopic mesh. The six sides have holes to connect with each other, and it is easy to bend into certain radian degree. It is spot-welded in inner wall of shell and then poured by refractory aggregate, which can increase service life by several times. Besides the refractory will not peel off and it has long service life. It is usually used in lining of wear-resistant materials, which enhances the anchoring ability of lining materials. There are many points to be noticed when using, hex steel should be welded with furnace or other inner walls. Fix them and smear by some refractory, which can increase high temperature resistance and wear resistance.

Index

hex mesh / hex metal / flexible metal / hex steel grid / hexagonal grid

Anping ZhongDi Wire Mesh Products Co.,Ltd

Tel.: +86-318-7879889

Fax: +86-318-7879810