- Home

- Products

- Woven Wire Mesh Series

- Special Material Wire Mesh

- Molybdenum Wire Mesh

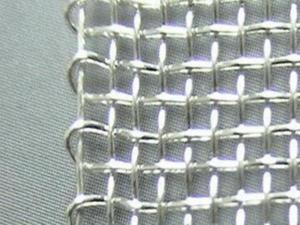

Molybdenum Wire Mesh

This product has been discontinued and removed from our shelves.

Name: Molybdenum wire mesh, Molybdenum mesh

ZhongDi can supply molybdenum wire mesh from 6 to 400mesh. Molybdenum has properties that are similar to tungsten, with a high strength to weight ratio, and is not subject to hydrogen embrittlement. The molybdenum wire mesh is often used in the metallurgical applications and chemical operations. It is extensively utilized in the applications that require aggressive heating, such as aircraft parts, electrical joints and commercial motors.

Melting point: 2610°C - 2640°C.

Weave Pattern: plain weave, twill weave, dutch weave.

Packing: waterproof paper with plastic cloth, then put into a wooden box.

Molybdenum wire Mesh: 6 mesh to 400 mesh.

Features of Molybdenum Wire Mesh:

High tensile strength, low elongation, acid and alkaline resistant, corrosion resistant, high temperature resistant, good electricity-conductivity, lightweight, various hole shapes, excellent filtering performance

Applications of Molybdenum Wire Mesh:

Molybdenum wire mesh has an excellent corrosion resistance, heat-conductivity and is widely used in high temperature fields for sieving and filtering. The main application fields of molybdenum wire mesh are: aerospace, nuclear power field, electro-vacuum industry, glass furnaces, petroleum, oil and gas industry, new energy industries, and food processing industry.

| Molybdenum Wire Mesh | |||||||||

| Mesh/Inch | Wire Diameter mm |

Opening mm |

Open Area % |

Weight (kg/m2) |

Mesh/Inch | Wire Diameter mm |

Opening mm |

Open Area % |

Weight (kg/m2) |

| 1 | 4.87 | 20.523 | 65% | 15.40 | 40 | 0.25 | 0.385 | 37% | 1.62 |

| 2 | 3.04 | 9.652 | 58% | 12.00 | 40 | 0.23 | 0.401 | 40% | 1.37 |

| 2 | 2.60 | 10.033 | 62% | 8.78 | 40 | 0.22 | 0.415 | 43% | 1.25 |

| 3 | 2.00 | 6.467 | 58% | 7.80 | 40 | 0.19 | 0.445 | 49% | 0.93 |

| 3 | 1.60 | 6.867 | 66% | 4.99 | 50 | 0.19 | 0.318 | 39% | 1.17 |

| 4 | 1.60 | 4.750 | 56% | 6.65 | 50 | 0.15 | 0.355 | 49% | 0.73 |

| 4 | 1.20 | 5.150 | 66% | 3.74 | 50 | 0.20 | 0.478 | 89% | 1.29 |

| 5 | 1.20 | 3.880 | 58% | 4.67 | 60 | 0.15 | 0.273 | 42% | 0.87 |

| 5 | 1.00 | 4.080 | 65% | 3.24 | 60 | 0.16 | 0.263 | 39% | 0.99 |

| 6 | 1.20 | 3.033 | 51% | 5.61 | 70 | 0.12 | 0.243 | 45% | 0.65 |

| 6 | 0.90 | 3.333 | 62% | 3.15 | 80 | 0.12 | 0.198 | 39% | 0.74 |

| 8 | 0.61 | 2.565 | 65% | 1.93 | 90 | 0.12 | 0.162 | 33% | 0.84 |

| 10 | 0.50 | 2.032 | 64% | 1.62 | 100 | 0.10 | 0.154 | 37% | 0.64 |

| 10 | 0.45 | 2.083 | 67% | 1.31 | 100 | 0.076 | 0.177 | 49% | 0.37 |

| 12 | 0.50 | 1.609 | 58% | 1.94 | 120 | 0.09 | 0.122 | 33% | 0.63 |

| 14 | 0.42 | 1.397 | 59% | 1.60 | 120 | 0.08 | 0.132 | 39% | 0.49 |

| 16 | 0.38 | 1.212 | 58% | 1.50 | 140 | 0.06 | 0.121 | 45% | 0.32 |

| 18 | 0.28 | 1.137 | 65% | 0.91 | 150 | 0.065 | 0.104 | 38% | 0.41 |

| 20 | 0.40 | 0.870 | 47% | 2.07 | 180 | 0.06 | 0.081 | 33% | 0.42 |

| 20 | 0.32 | 0.955 | 57% | 1.33 | 180 | 0.05 | 0.091 | 42% | 0.29 |

| 24 | 0.28 | 0.784 | 55% | 1.22 | 200 | 0.05 | 0.077 | 37% | 0.32 |

| 24 | 0.23 | 0.824 | 61% | 0.82 | 250 | 0.04 | 0.062 | 37% | 0.25 |

| 26 | 0.25 | 0.723 | 55% | 1.05 | 270 | 0.028 | 0.066 | 49% | 0.13 |

| 28 | 0.27 | 0.633 | 49% | 1.32 | 280 | 0.03 | 0.061 | 45% | 0.16 |

| 28 | 0.23 | 0.673 | 55% | 0.96 | 300 | 0.04 | 0.045 | 28% | 0.31 |

| 30 | 0.23 | 0.613 | 52% | 1.03 | 325 | 0.035 | 0.043 | 30% | 0.25 |

| 32 | 0.30 | 0.494 | 39% | 1.87 | 400 | 0.025 | 0.038 | 37% | 0.16 |

The table below shows the most popular specifications:

Molybdenum (UNS R03610) Chemical Composition %| C | Fe | Ni | O | Si | N | Mo |

| 0.01 | 0.01 | 0.005 | 0.007 | 0.01 | 0.002 | Rem |

Index

Molybdenum wire mesh / Molybdenum mesh / Molybdenum Wire Cloth